|

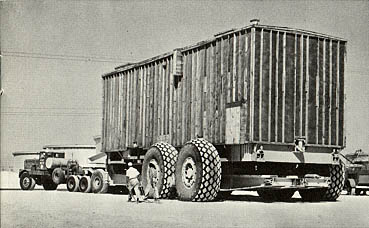

The portable pumping units weighed 125 tons each. They arrived by sea,

were hauled to their places on the line on giant trailers.

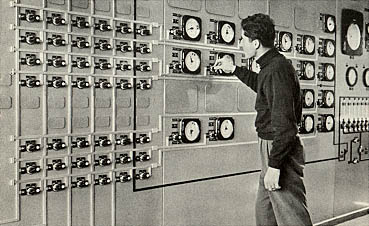

Electronically operated control board at Sidon terminal indicates

amount of oil being directed into one of the 20 storage tanks.

|

portable gas turbine pumping unit, and permits the line to continue to

operate safely.

From Shu'bah, Barrel X continues westward

through alternate base stations and portable gas turbine driven

pumping units at Rafha, 'Uwaigilah, Badanah, and Jalamid, 677

kilometers to Turaif, the most westerly operating location in Saudi

Arabia.

UNIQUE HYDRAULIC PUMP

Turaif has three electric-motor driven

centrifugal pumps, and two permanently mounted 5,000horsepower

gas-turbine driven centrifugal pumps, instead of the six diesel-driven

pumps used at the other three main pump stations. Turaif also has

another Tapline innovation: a booster pump driven by a part of the

hydraulic power supplied by the main gasturbine driven pumps. Here is

how it works:

After the oil leaves the main gas turbine

driven pumping units at high pressure, a small part of it is diverted

into the hydraulic turbine. This turbine is similar to a centrifugal

pump, except that highpressure oil is forced through it, causing it to

rotate. The rotation of the hydraulic turbine then drives a

conventional centrifugal booster pump, which boosts the main oil

stream to the suction pressure required for satisfactory operation of

the high speed gas-turbine driven pumps.

When Barrel X leaves Turaif, it moves 165

kilometers to Qaryatain, Jordan, where it is boosted by a permanently

mounted 5,000-horsepower gas turbine unit. This unit is controlled by

radio from Turaif. It functions in the same manner as the units at

Shu'bah, 'Uwaigilah and Jalamid, but the pumping unit and controls are

installed in a conventional building instead of in portable vans.

|

6

|